Introduction

Table Contents

- Introduction

- The Role of Blast Rooms in Surface Preparation

- Key Features of Modern Blast Rooms

- Advanced Ventilation Systems

- Dust Collection Technologies

- Media Recovery Systems

- Benefits of Implementing Advanced Blast Room Solutions

- Improved Safety for Workers

- Enhanced Product Quality

- Increased Operational Efficiency

- Case Study: Successful Integration of Blast Rooms in Manufacturing

- Considerations When Choosing a Blast Room

- Size and Configuration

- Type of Abrasive Media

- Industry-Specific Requirements

- Maintenance and Best Practices for Blast Room Operations

- Regular Maintenance Schedules

- Training Programs for Operators

- Conclusion

In industrial manufacturing, surface preparation is a crucial step that significantly impacts product quality, durability, and performance. Effective surface treatment ensures proper adhesion of coatings, prevents corrosion, and extends the lifespan of manufactured components. A key element in achieving optimal surface preparation is the implementation of a well-designed Blast Room. Airblast AFC, a leader in surface preparation and finishing solutions, specializes in designing, manufacturing, and installing blast rooms tailored to various industries, including aerospace, defense, oil & gas, marine, rail, transport, and energy sectors. Their expertise ensures that each blast room meets the specific needs of the application, providing a controlled environment for efficient and effective surface treatment.

The Role of Blast Rooms in Surface Preparation

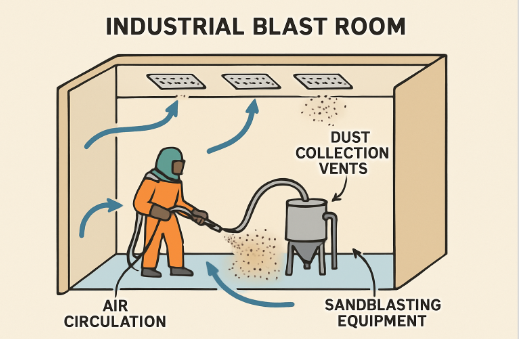

Blast rooms are enclosed environments where abrasive blasting processes are conducted to clean, smooth, or shape surfaces by forcibly propelling a stream of abrasive material against them. These rooms are essential for containing the blasting operation, thereby controlling dust, debris, and noise, which enhances safety and environmental compliance. By providing a controlled setting, blast rooms ensure consistent surface preparation, leading to improved coating adhesion and overall product quality.

Key Features of Modern Blast Rooms

Advanced Ventilation Systems

Modern blast rooms are equipped with sophisticated ventilation systems designed to maintain air quality and visibility. These systems effectively remove airborne contaminants, such as dust and abrasive particles, ensuring a safe working environment for operators. Proper ventilation also prevents the accumulation of hazardous materials, reducing the risk of respiratory issues and other health concerns.

Dust Collection Technologies

Effective dust collection is crucial in blast room operations to comply with environmental regulations and protect worker health and safety. Advanced dust collection systems capture and filter out fine particles generated during blasting, preventing their release into the surrounding environment. This not only maintains air quality but also minimizes cleanup time and equipment wear.

Media Recovery Systems

Media recovery systems are integral to modern blast rooms, allowing for the efficient collection and reuse of abrasive materials. These systems reduce waste and operational costs by recycling media, ensuring a consistent supply of abrasives for continuous operations. Various recovery methods, such as pneumatic, mechanical, or vacuum systems, can be tailored to specific operational needs.

Benefits of Implementing Advanced Blast Room Solutions

Improved Safety for Workers

Advanced blast rooms are designed with operator safety in mind. Features such as proper ventilation, dust collection, and containment systems minimize exposure to hazardous materials, thereby reducing the risk of respiratory issues and other health hazards. Additionally, ergonomic designs and automated controls further enhance worker safety and comfort.

Enhanced Product Quality

Consistent and thorough surface preparation achieved through advanced blast room solutions leads to superior product quality. Uniform surface treatment ensures better coating adhesion, resulting in products that are more durable and resistant to environmental factors such as corrosion and wear.

Increased Operational Efficiency

The integration of modern technologies in blast rooms streamlines the surface preparation process. Efficient media recovery systems, automated controls, and effective dust collection reduce downtime and maintenance requirements, leading to higher throughput and cost savings.

Case Study: Successful Integration of Blast Rooms in Manufacturing

A notable example of successful blast room integration is the collaboration between Airblast AFC and Johnson Thermal Systems (JTS). JTS, a company specializing in generator enclosures for critical backup power systems, opened a new 172,000-square-foot manufacturing facility in Nampa, Idaho. Airblast AFC designed, supplied, and installed industrial blast and spray facilities at this new site, ensuring that each enclosure is finished to the highest standards for performance, protection, and reliability. This partnership highlights the impact of advanced blast room solutions on enhancing manufacturing efficiency and product quality.

Considerations When Choosing a Blast Room

Size and Configuration

Selecting the appropriate size and configuration of a blast room is crucial to accommodate the specific dimensions and shapes of the workpieces being processed. Customizable options, such as modular or containerized designs, offer flexibility to meet diverse operational requirements.

Type of Abrasive Media

The choice of abrasive media depends on the material of the workpiece and the desired surface finish. Blast rooms should be compatible with various media types, including steel grit, glass beads, or plastic media, to ensure optimal results.

Industry-Specific Requirements

Different industries have unique standards and regulations governing surface preparation. It’s essential to choose a blast room solution that complies with industry-specific requirements, such as those in aerospace, automotive, or marine sectors.

Maintenance and Best Practices for Blast Room Operations

Regular Maintenance Schedules

Implementing a routine maintenance schedule ensures that all components of the blast room, including ventilation systems, dust collectors, and media recovery units, function optimally. Regular inspections and timely repairs prevent unexpected downtime and extend the lifespan of equipment.

Training Programs for Operators

Comprehensive training programs equip operators with the knowledge and skills to use blast room equipment safely and effectively. Training should cover proper equipment handling, safety protocols, and emergency procedures to maintain a safe working environment.

Conclusion

Incorporating advanced blast room solutions into industrial manufacturing processes offers numerous advantages, including improved worker safety, enhanced product quality, and increased operational efficiency. By carefully selecting and maintaining the appropriate blast room systems, manufacturers can achieve superior surface preparation results, leading to products that meet the highest standards of performance and durability.