Every day Australian families pour new milk into their coffee, cereal bowls or drink it straight from the glass. Have you wondered about the extraordinary journey that milk has to travel before it ends up on your kitchen shelf? By knowing where our own food comes from, we can make better-informed choices and better understand the hard work that is invested in providing us with life’s necessities that we so often take so much for granted.

Life as a Dairy Farmer

Table Contents

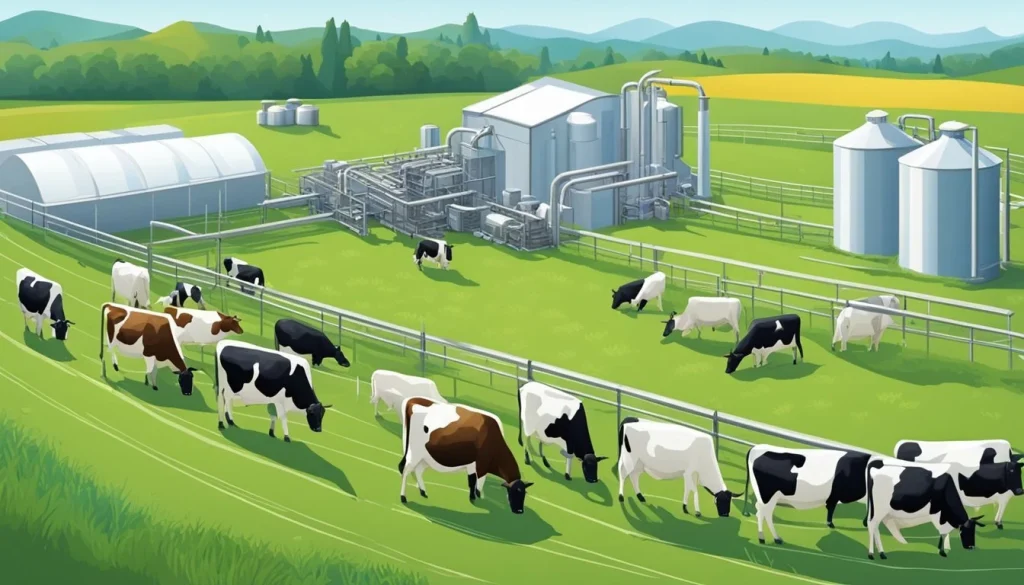

Australian dairy farms have cows grazing all over the country, from Victoria to Tasmania’s coastal pastures. These Holstein-Friesian- and Jersey-based cows are mostly pastured on high-nutrient pasture and supplementary feed. Farmers work hard to control their diets in order to have their cows produce a lot of milk, as well as keep them in good health.

Current Australian dairy farms focus on animal well-being, ensuring comfortable living quarters, frequent visits to a veterinarian, and stress-free living. Cows generally give milk for roughly 10 months per year and will have a two-month resting phase prior to entering into their subsequent lactation cycle.

The Milking Technique

The majority of Australian dairy farms have automated milking systems that milks twice a day, sometime in the early morning and evening afternoons. Cows voluntarily enter milking parlours, where they are cleaned and set up to be milked.

Tight hygiene standards regulate this procedure. Farmers disinfect machinery prior to and after usage and cool milk to 4°C instantly to hinder bacteria development. Present day milking machines simulate a calf suckling rhythm to keep cows comfortable yet preserve milk quality.

Transport to Processing

Once harvested, milk is transported from farm to plant in special refrigerated vehicles. These keep the cold chain intact, holding milk at its best temperatures during shipment. Australian milk is typically transported to a plant within 24-48 hours of its exit from a cow.

During collection, samples are prepared to test their quality. This enables only those milks that have passed through stern standards of quality and safety to reach the next step of its journey.

Processing and Pasteurisation

In the processing plant, milk goes through a number of important stages. It is checked again for quality and safety. Next is pasteurisation – a form of heat treatment that kills harmful bacteria yet-retains nutritional content. Australia pasteurises most of its milk at 72°C for 15 seconds.

Homogenisation follows, which further breaks down fat globules to create a smooth, even consistency to eliminate separation of cream. This step provides to the milk its regular appearance and mouthfeel expected by Australian customers.

Packaging to Protect

Packaged farm fresh milk comes in all types of containers, from familiar plastic bottles to cardboard cartons to glass bottles. These have different virtues: plastic is lightweight and cannot be broken, cartons of cardboard can be recycled, and glass bottles can be refilled.

Numerous Australian dairy firms invest in environmentally friendly packaging methods as a reaction to customer pressure to provide such alternatives. Some of them have launched plant-based packing or added recycled material content to their containers.

Quality Control

Quality control measures operate at every stage of milk’s journey. From farm inspections and regular testing to processing plant monitoring and packaging checks, multiple safeguards ensure Australian milk meets world-class safety standards.

The Australian dairy industry is subject to rigorous regulation by Food Standards Australia New Zealand to guarantee a consistent product from farm to table.

Supporting Australian Dairy

Seeing how milk goes from cow to carton is an eye-opener to the skill and commitment it takes to bring this healthy staple to our tables. When we buy Australian-made dairy foods, we’re promoting our country’s farmers and farms, as well as sustained productivity to feed successive generations of Australian families.